Industrial Process News is proud to announce that Vision Engineering has been chosen to receive our Optical Instrumentation Company of the Year Award, for its outstanding commitment to the advancement of both its world-leading products and expert staff, adding value to an extensive range of industries.

Vision Engineering, a privately owned, British company, has consistently delivered leading-edge stereo inspection and non-contact measurement products, using leading edge optical or digital technology to improve productivity and quality for thousands of companies. The company’s strategic focus is on optimising the user interface and the development of truly ergonomic systems. Operators who use instruments for sustained, repetitive, shift patterns or who need to work very intensively in short bursts, with high accuracy requirements, experience physical and mental stresses which reduce their efficiency in terms of throughput, accuracy or scrap rate.

Vision Engineering, a privately owned, British company, has consistently delivered leading-edge stereo inspection and non-contact measurement products, using leading edge optical or digital technology to improve productivity and quality for thousands of companies. The company’s strategic focus is on optimising the user interface and the development of truly ergonomic systems. Operators who use instruments for sustained, repetitive, shift patterns or who need to work very intensively in short bursts, with high accuracy requirements, experience physical and mental stresses which reduce their efficiency in terms of throughput, accuracy or scrap rate.

Vision Engineering is constantly developing technologies to reduce postural or optical stress and to optimise sensory engagement with the work in hand or the working environment.

The company has achieved unprecedented success since its establishment in 1958, and we had the pleasure of speaking to Mark Curtis, Group Managing Director, who told us more about the work behind these impressive achievements.

“We are 99% focused on manufacturers who make something which is safety or quality critical, such as in the medical or aerospace sector, or on manufacturers who concentrate on maintaining a competitive edge, such as high-end automotive companies manufacturing electric and hybrid vehicles who are moving technology forward as well as maintaining quality. Similarly, we work with mobile phone manufacturers who are competing by making products with increasing numbers of features while maintaining reliability.

“This all means that we work with either big manufacturers or their supply chains; we figure out what’s important to the big company, and then we work with the entire supply chain to ensure these standards are upheld. This is why Vision Engineering, in addition to 125 staff at manufacturing sites and HQ in the UK, Vision Engineering has around 150 staff members based outside of the UK, and 90% of the business is in export – the big companies have supply chains located around the world, so we need to ensure we have a global network of capable engineers to provide consistent levels of support no matter where a customer is. At present our biggest markets are North America, the EU (particularly Germany), but with China and South East Asia catching up fast.”

Indeed, Vision Engineering has remained sensitive to the fluctuating demands of its customers for over 60 years. 15 years ago, there was a focus on the electronics industry where there was a need to remove toxic metals from its products. Changes from heavy metals to non-lead resulted in a range of manufacturing challenges for electronics manufacturers, which Vision Engineering was able to help analyse, inspect, measure, resulting in minimised disruption to quality and throughput. Any changes to a technological process can create a host of challenges, and Vision Engineering helped companies to address these.

Now, there are developments in the automotive sector, which is moving towards electric, hybrid or cleaner combustion engines. Furthermore, in the medical industry, there is a focus on developing biological materials for coating implants and on bone reconstruction technology, while in sustainable energy there is lots of work being done on efficiency, storage and usage of renewable energy sources. “When somebody enters a new technological process, it poses challenges as a company needs to meet new standards. Vision Engineering can help whenever a customer is trying to push the technological envelope.

“We always attend numerous trade shows, in a wide variety of vertical sectors, to stay abreast of the industry, discover issues and then develop our technology to address them. We invest heavily in our Research and Development to ensure we consistently deliver what our customers need. For example, the latest trends are towards haptic engagement. Haptics is a concept, largely driven by German leading manufacturers, which emphasises the need for a user to engage on a sensory level with the instruments they are using. This can be though soft touch, optimally located controls, or through sight and sound. Our latest products focus on user interfaces, including haptic technologies.”

The company’s flagship product, the Mantis, was the world’s first stereo microscope without an eyepiece, designed to fill the gap between a bench magnifier and a microscope. This was a major ergonomic revolution, and it went on to win numerous design and innovation awards. Mantis became the new benchmark for high performance stereo magnification, and since then, Vision Engineering has made constant improvements to the technology to keep up with changing demands, and is currently in the process of developing the fourth generation of the microscope.

In line with the Company strategy of addressing the latest technological trends, Vision Engineering has recently been focusing on the global drive towards Virtual/Augmented Reality and communication of Real Time information. The wide interest in the Internet Of Things (IoT), Industry 4.0, Blockchain and the development of 5G is driven by the need to have accurate, comprehensive information, which can be communicated anywhere within a global multinational operation, around multiple location supply chains, or between centres of excellence

Three months ago, Vision Engineering launched its Deep Reality Viewer, DRV-Z1, the world’s first 3D stereo viewer for which the company has global patents. DRV addresses the disadvantages of sensory isolation and disorientation, meaning users can work more comfortably, for longer, wear their own prescription glasses and interact freely with their colleagues onsite. In addition, communication over wired or wireless media enables users to interact, in real time, with their colleagues or reference sites who are elsewhere, even in other parts of the world. Manufacturing sites will now be able to share best practice, fault finding/troubleshooting and consult, looking at the same, live, real-time images.

The DRV-Z1’s stereo digital image without headsets or specialised glasses provides a natural 3D view, with a high definition resolution to enable better quality inspection. Without the need for special glasses/headsets, Vision Engineering’s unique device allows freedom of head movement, natural subject view, comfortable working position, easy hand-to-eye coordination, and the ability to wear prescription eye glasses.

“After launching the DRV earlier this year, it has been taken with great interest around the world, with initial sales on a global scale. This was the first device in a family, and we have a five-year plan in place to exploit this patented core technology in a variety of situations. The first two devices were directed at our current markets, and now we are developing the range to make it appropriate for a broader range of markets, such as in drone and satellite scans and MRI scanning. It’s all about exploiting the technology in different forms.”

“After launching the DRV earlier this year, it has been taken with great interest around the world, with initial sales on a global scale. This was the first device in a family, and we have a five-year plan in place to exploit this patented core technology in a variety of situations. The first two devices were directed at our current markets, and now we are developing the range to make it appropriate for a broader range of markets, such as in drone and satellite scans and MRI scanning. It’s all about exploiting the technology in different forms.”

The Deep Reality Viewer R&D programme took three years and was supported by significant Innovate UK R&D & market analysis grants.

Indeed, Vision Engineering has a constant rolling programme of various projects to ensure they are always addressing the pertinent challenges within various industries. “We are confident about what the next 12 months will bring and the selection of new products we will be releasing,” explained Mark.

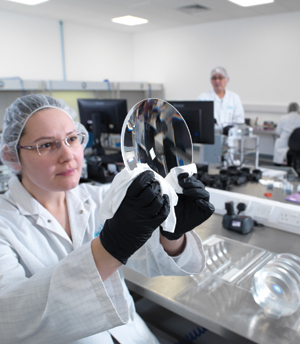

“High end manufacturing needs high end facilities”, stated Mark. “To this end, two years ago we built from scratch and have now occupied state of the art R&D, manufacturing and Global HQ facilities of 84,000 ft2 in Woking, Surrey. Being able to design and build a facility meant that we could incorporate the latest Lean manufacturing techniques and full development and testing labs. It enabled us to compete on the world stage and means that we now have a total of 130,000 ft2 of modern, full service manufacturing space, which includes a wholly owned factory in Connecticut, USA.”

As well as an unwavering dedication to product advancement, Vision Engineering is committed to the ongoing development of its expert staff, focusing on staff retention and running active apprenticeship schemes to teach a full range of skills to budding engineers.

“We are also increasing the drive of our e-marketing and social media. We have recently configured our website to be used on mobile devices as well as computer screens – our stats showed that an increasing number of people were accessing our site using a mobile device, so we put motions in place to ensure they were getting a valuable experience from visiting our webpage, no matter what device they were using.

“There are also more people using social media, and so we are utilising this to help our customers stay abreast of our products even when they’re not looking for them. This means they remain aware that Vision Engineering is constantly working and researching, with innovative products in the pipeline that may be of value to them. To add to this, we are producing webinars to provide flexible and interactive information which can be in front of both potential and existing customers immediately.”

Certainly, it is clear to see how Vision Engineering is remaining at the forefront of innovation and cementing its status as an industry leader. “It’s great to receive this Company of the Year award,” concluded Mark. “The interesting thing is that it’s also great internally; it’s good for people to feel like the broader world is taking note of their hard work.”

If you would like to find out more information, head to the website or use the contact details below.

Contact

T 01483 248300

www.visioneng.com