People buy PEMAC software to make better Engineering decisions, optimise Preventative Maintenance strategies, reduce equipment downtime and enhance compliance.

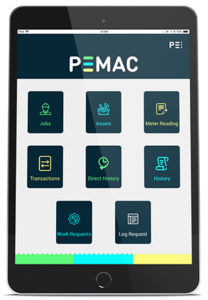

PEMAC integrates all the benefits of a world-class maintenance management solution with a comprehensive suite of health & safety tools, all in a single intuitive platform. Plan, track and report on all of your equipment and your people using our smarter CMMS automated intelligence system.

PEMAC integrates all the benefits of a world-class maintenance management solution with a comprehensive suite of health & safety tools, all in a single intuitive platform. Plan, track and report on all of your equipment and your people using our smarter CMMS automated intelligence system.

PEMAC software offers safer working environments with improved production performance and lower maintenance costs.

Tracking all equipment and stock, maintenance tasks and routines with Contractor and Permit Management are core to PEMAC Assets. With more than 200 features, PEMAC Assets is a fully customisable software solution allowing full Predictive Maintenance planning using IOT technology.

Tracking all equipment and stock, maintenance tasks and routines with Contractor and Permit Management are core to PEMAC Assets. With more than 200 features, PEMAC Assets is a fully customisable software solution allowing full Predictive Maintenance planning using IOT technology.

Users can select, combine, and integrate multiple PEMAC Assets modules into one platform. PEMAC Assets protects the health & safety of your staff and contractors and manage change approval in a 100% paperless environment.

PEMAC Assets can also work across multiple sites with multiple languages and currencies and can easily integrate with existing ERP, OEE and financial platforms. The CMMS system also supports compliance of 21CFR, on site validations, enables calibrations which can all be backed up with live reporting supporting LEAN and AMIS operations.

PEMAC continually updates its product with enhancements to its premium features. PEMAC Assets is available on mobile when the device is in Offline mode. For example, Food Manufacturers may have staff working outside with no network access, and larger Manufacturing Plants often lose access deeper into the production facility. With PEMAC Assets now available offline, tracking and recording activities does not have to stop.

PEMAC continually updates its product with enhancements to its premium features. PEMAC Assets is available on mobile when the device is in Offline mode. For example, Food Manufacturers may have staff working outside with no network access, and larger Manufacturing Plants often lose access deeper into the production facility. With PEMAC Assets now available offline, tracking and recording activities does not have to stop.

Mobile Users can manually switch to offline mode, or if connectivity drops they will be prompted to switch offline. Once back online, all data is automatically synchronised ensuring accuracy of records. There are also additional fail-safes such as automatically locking jobs that have been taken offline for Online users, ensuring no duplication of work.

Below are some of the features which are available offline:

- Details of Assets, History, attributes and corresponding Work Orders

- The ability to record actions, complete tasks and create Follow-on orders & add Resources to offline jobs

- Associated Job attachments appear plus the device camera is integrated with automatic upload

- Record Calibration test results

- Commit to or cancel Spare Parts

- Warnings & Defect Analysis

A PEMAC Success story

Viatris (formerly Mylan Dublin) operates in pharmaceutical manufacturing and is currently one of the biggest names in the sector, exporting to 86 countries from its Irish plant. Following a major acquisition, it was identified that improvements were required in its maintenance operations.

Viatris (formerly Mylan Dublin) operates in pharmaceutical manufacturing and is currently one of the biggest names in the sector, exporting to 86 countries from its Irish plant. Following a major acquisition, it was identified that improvements were required in its maintenance operations.

Challenges

Viatris was facing a number of challenges, including doubling the output of their finished products and changing their maintenance operation to reduce costs. Their parent company wanted them to increase efficiency as well as decrease equipment downtime. Many of the Maintenance activities were unplanned, the system largely paper-based, and a typical preventative maintenance job took 16 steps to be completed. It was clear that improvements in costs, effectiveness and downtime were needed.

Solutions

By applying the PEMAC Maintenance system, including its Web Workflow tool, Viatris would be in a position to achieve their core objectives:

- Paperless Maintenance: The system facilitated the implementation of a paperless maintenance system from work request right through to closing the job. No paper is used in any aspect of maintenance work. This has enabled improved efficiency, remote approval and an environmental benefit.

- Intelligent Reporting: PEMAC Intelligent reporting allowed Viatris to achieve best practice in preventative maintenance and enable them to reduce costs, improve operations and maximise uptime.

- Web Workflow: Using the Web Workflow tool, technicians would now be able to view both planned and unplanned work through one interface.

- Quick Implementation: Turnaround for full implementation of PEMACs system was less than 6 months allowing Viatris to experience the benefits and cost savings early.

Results

The results saw Viatris achieve a fully paperless maintenance environment removing 1 million wet signatures from their workflows. They experienced a 64% decrease in maintenance costs, an increase in planned maintenance activities from 80% unplanned to 80% planned within 2 years and a significant reduction in equipment downtime. A typical preventative maintenance job was now reduced from a 16-step paper process to just 4 steps. Viatris also removed 54% of their non-value-added Preventative Maintenance routines once PEMAC was in place, which translated into a 75% saving on Engineering time. Mean time between failures (MTBF) also went from 150 minutes to a high of 500 minutes within one year. Overall, these gains were key to bringing Viatris a host of awards and accolades in recent years.

The results saw Viatris achieve a fully paperless maintenance environment removing 1 million wet signatures from their workflows. They experienced a 64% decrease in maintenance costs, an increase in planned maintenance activities from 80% unplanned to 80% planned within 2 years and a significant reduction in equipment downtime. A typical preventative maintenance job was now reduced from a 16-step paper process to just 4 steps. Viatris also removed 54% of their non-value-added Preventative Maintenance routines once PEMAC was in place, which translated into a 75% saving on Engineering time. Mean time between failures (MTBF) also went from 150 minutes to a high of 500 minutes within one year. Overall, these gains were key to bringing Viatris a host of awards and accolades in recent years.

“We’re very satisfied with the success of the implementation. It has not only enabled us to achieve our objectives, but it has continued to provide us with significant additional benefits for our operations. PEMAC provided us with a high level of support throughout the process and continues to do so today. We would have no hesitation in recommending PEMAC and their innovative software solutions to any company.”

“We’re very satisfied with the success of the implementation. It has not only enabled us to achieve our objectives, but it has continued to provide us with significant additional benefits for our operations. PEMAC provided us with a high level of support throughout the process and continues to do so today. We would have no hesitation in recommending PEMAC and their innovative software solutions to any company.”

Wesley Horan – Senior Engineering Operations Director, Viatris Dublin

PEMAC Assets is available as SAAS or as an on-premise solution and implemented with support by the PEMAC team. Whether you are a large enterprise with a global footprint or just taking the first steps in implementing a CMMS, PEMAC has a solution for you. PEMAC is based in Cork, Ireland with offices in Dublin and Manchester, UK.

For more information:

T +44 (0)161 509 2492

sales@pemac.com

www.pemac.com