Industrial Process News is proud to announce that Zen Production Equipment Limited (ZPEL) has been selected as our Electronic Production Equipment Company of the Year, for their outstanding commitment to supplying the finest quality equipment for the electronics manufacturing industry.

Established in 2006, ZPEL has since developed a stellar reputation as a reliable supplier of the most appropriate electronic production equipment for each company they work with. Their management team has over 30 years’ experience in all the key aspects of electronics production equipment, and they have travelled to a wide range of countries in order to find the highest quality products in each sector of electronics production engineering. This means that their equipment is unrivalled for value in the marketplace, and each customer can guarantee that they are receiving the highest quality products available.

Established in 2006, ZPEL has since developed a stellar reputation as a reliable supplier of the most appropriate electronic production equipment for each company they work with. Their management team has over 30 years’ experience in all the key aspects of electronics production equipment, and they have travelled to a wide range of countries in order to find the highest quality products in each sector of electronics production engineering. This means that their equipment is unrivalled for value in the marketplace, and each customer can guarantee that they are receiving the highest quality products available.

Speaking to Managing Director, Peter Clarke, he expressed that he is thrilled that ZPEL has been selected as our Company of the Year: “The past 12 months have seen a good order book as well as some very interesting large projects which are still being worked on. We are extremely happy and of course proud to have won the award and to have been recognised for our hard work.”

The majority of ZPEL’s equipment is sourced from the industry’s leading suppliers, all of which sell to businesses worldwide including many of the world’s leading OEM and CEM electronics companies. Some of ZPEL’s most loyal customers include manufacturers such as ZF Group, Sony, Honeywell, McLaren and Kentec, as well as an extensive selection of subcontract manufacturers.

One of their suppliers, Asscon, specialises in Vapour Phase Technology, which is also known as Condensation Soldering. Their equipment uses vapour as an energy transfer medium, which is one of the most efficient procedures for heating assemblies. Asscon products therefore are ideal for use from prototype to final production. They save time and money in the workplace and boast low operating costs as a result of low energy requirements.

One of their suppliers, Asscon, specialises in Vapour Phase Technology, which is also known as Condensation Soldering. Their equipment uses vapour as an energy transfer medium, which is one of the most efficient procedures for heating assemblies. Asscon products therefore are ideal for use from prototype to final production. They save time and money in the workplace and boast low operating costs as a result of low energy requirements.

Another leading supplier, Inertec, has released the new CUBE.460 soldering system, which is a production cell for small and medium batch sizes. Users can perform THT assembly directly on the machine thanks to the loading shuttle, as well as improve the quality of the soldering when compared to manual processes. The system’s simplified graphical programming allows quick entry into selective soldering technology, and the user can benefit from the professional functions and proven technology available in larger systems, such as process monitoring or bus-capable DC servomotors.

Heller, another of ZPEL’s excellent suppliers, are a world leader in Reflow Oven Technology, using the most advanced production systems available in order to provide the user with consistent performance for high Mix / high volume requirements. The ovens also help to minimise preventative maintenance costs as well as taking up minimal floor space. The Mark5 Series delivers up to a 40% reduction in electrical and nitrogen consumption, meaning the machines have the best overall value in the industry.

Heller, another of ZPEL’s excellent suppliers, are a world leader in Reflow Oven Technology, using the most advanced production systems available in order to provide the user with consistent performance for high Mix / high volume requirements. The ovens also help to minimise preventative maintenance costs as well as taking up minimal floor space. The Mark5 Series delivers up to a 40% reduction in electrical and nitrogen consumption, meaning the machines have the best overall value in the industry.

In 2018, ZPEL took on two new excellent suppliers, Aurotek in Taiwan, and Essemtec AG in Switzerland. Aurotek supply a range of PCBA profiling equipment ranging from simple desktop solutions to high volume inline systems. Essemtec AG offer a range of pick and place systems, dispensing systems and component storage solutions. “As far as we are aware,” says Peter, “their pick and place systems are the only ones that can offer dispensing on the same platform as pick & place.”

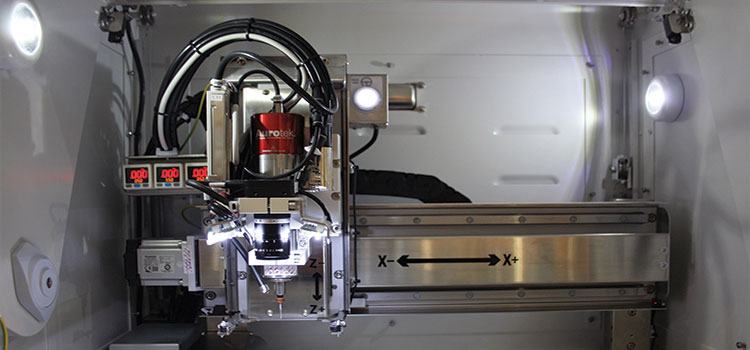

Essemtec AG supply smart and highly flexible SMT Solutions, including the Fox and Puma Pick & Place systems which can offer multiple heads for P&P, as well as dispensing on a single platform. The Fox and Puma can both be used as stand-alone systems or be configured as inline solutions, and there are also the Spider and Tarantula systems which have a range of nozzle technologies purely for dispensing. All the systems use mineral cast beds for vibration free production as well as benefiting from no warping caused by thermal drift. They use linear motors throughout in order to give the highest accuracy with zero maintenance, and have one of the most comprehensive software packages available. As well as these, Essemtec AG has the Cubus and Cubus Large Component Towers, which offer the flexible storage of SMD reels in a range of sizes, trays, and boxes. The towers reduce logistic problems by 95% and offer full interface to most production systems and all major ERP and material management.

ZPEL are based in Long Eaton, just outside Nottingham, and in January 2019 they moved to a new location across the road from their previous office. We asked Peter about what this means for the company’s future: “At our new premises, we can now locate everything centrally. This gives us the opportunity to service our customers and suppliers far more efficiently. We have the possibility to have a demonstration area for our equipment here as well, and intend to bring in some key equipment so we can demonstrate it to potential customers.”

ZPEL are based in Long Eaton, just outside Nottingham, and in January 2019 they moved to a new location across the road from their previous office. We asked Peter about what this means for the company’s future: “At our new premises, we can now locate everything centrally. This gives us the opportunity to service our customers and suppliers far more efficiently. We have the possibility to have a demonstration area for our equipment here as well, and intend to bring in some key equipment so we can demonstrate it to potential customers.”

With an impressive 12 months behind them, Zen Production Equipment Limited are cementing their status as one of the UK’s leading suppliers of electronic production equipment, offering dedicated customer service and excellent after sales support. If you would like to find out more information, head to their website or use the contact details below.

T 01159 722733

www.zpel.co.uk