In this issue of Packaging, Warehouse & Logistics, we are pleased to feature Checkpoint Systems as our Security & Loss Prevention Company of the Year.

With roots stretching back to 1969, Checkpoint Systems has evolved from a specialist in loss prevention and electronic article surveillance into a global leader in radio-frequency identification (RFID), RF technology and connected solutions. Today, the company plays a pivotal role in reshaping how products are tracked, protected and managed from source to shelf across packaging, warehousing and logistics environments.

With roots stretching back to 1969, Checkpoint Systems has evolved from a specialist in loss prevention and electronic article surveillance into a global leader in radio-frequency identification (RFID), RF technology and connected solutions. Today, the company plays a pivotal role in reshaping how products are tracked, protected and managed from source to shelf across packaging, warehousing and logistics environments.

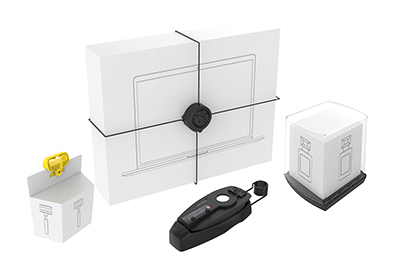

At the heart of Checkpoint’s impact is its ability to combine hardware, software, labels, tags and cloud-based platforms into fully integrated technology ecosystems. These solutions are designed to meet the complex demands of modern retailers, logistics providers and distribution centres, where real-time visibility, operational efficiency and loss mitigation have become business-critical priorities. As omnichannel fulfilment models expand and supply chains grow more complex, the need for reliable, data-driven inventory intelligence has never been greater.

Checkpoint’s vertically integrated operating model sets it apart within the market. By designing, developing and manufacturing its solutions entirely in-house across its lines of business, the company maintains complete oversight of every stage of the product lifecycle. This approach enables rigorous quality control, rapid innovation and consistent performance – from research and development through to deployment and post-sale support – while giving customers confidence that their solutions are built for long-term reliability and scalability.

Checkpoint’s vertically integrated operating model sets it apart within the market. By designing, developing and manufacturing its solutions entirely in-house across its lines of business, the company maintains complete oversight of every stage of the product lifecycle. This approach enables rigorous quality control, rapid innovation and consistent performance – from research and development through to deployment and post-sale support – while giving customers confidence that their solutions are built for long-term reliability and scalability.

To understand how the business has performed over the past year and where it is heading next, we sat down with Jenny Parisi – Sales and Marketing Director UK to discuss Checkpoint’s recent momentum, strategic priorities and future plans.

Reflecting on the past 12 months, Jenny described 2025 as a particularly dynamic year for the business.

“2025 was a very busy year for us. From strengthening relationships with existing customers to building new ones, we’ve continued to drive our business deeper into the logistics industry,” she explained. “The potential RFID has for warehousing is immense, and this will only continue to grow in 2026.”

That momentum has been driven in part by growing market demand for RFID-enabled solutions that go beyond traditional inventory tracking. Over the course of the year, Checkpoint secured several significant software projects while also seeing a marked increase in interest in RFID from both new and existing customers. Jenny noted that this reflects a broader shift in how organisations view RFID – not just as an operational tool, but as a strategic enabler.

“We’re seeing much greater interest in how RFID can deliver efficiency, visibility and loss prevention simultaneously,” she said. “Solutions such as our SFERO RFID as EAS antenna demonstrate how businesses can combine product protection with detailed inventory insight, allowing customers who previously relied on RF technology to evolve their approach without compromising security.”

“We’re seeing much greater interest in how RFID can deliver efficiency, visibility and loss prevention simultaneously,” she said. “Solutions such as our SFERO RFID as EAS antenna demonstrate how businesses can combine product protection with detailed inventory insight, allowing customers who previously relied on RF technology to evolve their approach without compromising security.”

Beyond product development, Checkpoint has also invested heavily in customer engagement and internal capability. One notable initiative in 2025 was the expansion of its Newbury showroom, designed to provide customers with hands-on exposure to the company’s full solution portfolio. The space serves as a hub for live demonstrations, customer meetings and comprehensive training, supporting both sales and engineering teams while helping clients visualise how different technologies can be deployed within their own operations.

Industry engagement has also played an important role in the company’s continued growth. During the year, Checkpoint attended several major sector events, including the Retail Technology Show, where it showcased its RFID capabilities alongside its Apparel Labelling Solutions team. The business also attended Tomorrow’s Warehouse for the first time, an event Jenny described as a valuable opportunity to engage directly with logistics leaders and demonstrate the transformative role RFID can play within distribution environments.

“Tomorrow’s Warehouse was an incredible opportunity for us,” she said. “It allowed us to highlight how RFID can simplify warehousing processes, improve asset management and ultimately change the way distribution centres operate. In 2026, we plan to attend even more events like these and continue expanding our reach across multiple industries.”

Checkpoint’s RFID solutions are designed to enable item-level traceability throughout the supply chain, helping businesses reduce stock discrepancies, accelerate replenishment cycles and optimise labour utilisation. These benefits are particularly valuable in highly automated environments, where precision and data accuracy are essential. Beyond tracking, the company’s RFID innovations support smarter packing processes, automated pallet validation and improved shipment accuracy, enabling organisations to respond quickly to changing market conditions.

Checkpoint’s RFID solutions are designed to enable item-level traceability throughout the supply chain, helping businesses reduce stock discrepancies, accelerate replenishment cycles and optimise labour utilisation. These benefits are particularly valuable in highly automated environments, where precision and data accuracy are essential. Beyond tracking, the company’s RFID innovations support smarter packing processes, automated pallet validation and improved shipment accuracy, enabling organisations to respond quickly to changing market conditions.

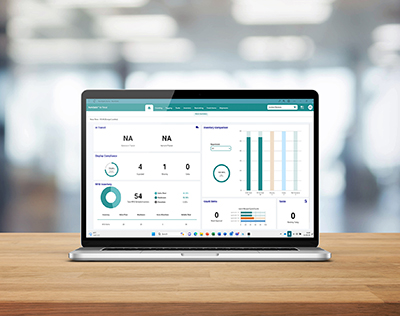

As customer priorities continue to shift, Checkpoint has observed increased demand for data-driven platforms that can deliver actionable insight alongside operational control. In response, the company’s ItemOptix Software platform has become a cornerstone of its offering, providing retailers and logistics operators with comprehensive visibility across their entire inventory ecosystem.

ItemOptix enables end-to-end inventory management, loss prevention, asset tracking and shipment validation across stores, suppliers and distribution centres. It also supports visual merchandise management and advanced reporting, helping businesses gain deeper insight into customer behaviour, purchasing trends and stock performance.

“For software, ItemOptix is unmatched in terms of flexibility and capability,” Jenny explained. “It allows customers to tailor the platform to their specific operational needs with ease. On the hardware side, our SFERO RFID as EAS antenna delivers combined product protection and inventory control, while our RFID tunnels and tables give distribution centres exceptional asset visibility. Alongside this, we offer an extensive portfolio of RFID labels designed for virtually every use case.”

“For software, ItemOptix is unmatched in terms of flexibility and capability,” Jenny explained. “It allows customers to tailor the platform to their specific operational needs with ease. On the hardware side, our SFERO RFID as EAS antenna delivers combined product protection and inventory control, while our RFID tunnels and tables give distribution centres exceptional asset visibility. Alongside this, we offer an extensive portfolio of RFID labels designed for virtually every use case.”

Checkpoint’s differentiation is further reinforced by the depth of its technical expertise. The company employs more than 635 highly experienced R&D, field service and software engineers, ensuring that every solution is installed and supported with precision and care. Dedicated specialist sales teams also guide customers throughout the purchasing journey, helping them identify the most effective technologies for their packaging, warehousing and logistics operations.

Operating on a truly global scale, Checkpoint Systems employs over 5,000 people across 35 countries and extends its reach into more than 55 additional markets through a strong network of partners. This global footprint allows the company to deliver consistent service and support worldwide while maintaining the agility required to meet local market demands.

Reflecting on some of the organisation’s key achievements in 2025, Jenny highlighted several milestones that underscore Checkpoint’s commitment to quality, sustainability and growth.

“At the beginning of the year, we were extremely proud to achieve ARC Quality Certification for 2025,” she said. “Issued by the Auburn University RFID Lab, this certification guarantees the compatibility and performance of RFID tags, ensuring customers receive reliable, cost-effective solutions.”

“At the beginning of the year, we were extremely proud to achieve ARC Quality Certification for 2025,” she said. “Issued by the Auburn University RFID Lab, this certification guarantees the compatibility and performance of RFID tags, ensuring customers receive reliable, cost-effective solutions.”

Sustainability has also remained a core focus for the business. In May, Checkpoint’s carbon reduction targets were officially verified through the Science Based Targets initiative (SBTi), reinforcing the company’s commitment to both near-term and long-term environmental goals.

In July, the company announced the opening of a new manufacturing facility in Mexico City, creating 100 jobs and strengthening its capacity to serve the North American market. Strategically located to improve responsiveness and streamline supply chain operations, the facility represents a significant investment in regional growth and global scalability.

“With the support of more than 200 CCL plants worldwide, we offer an unparalleled RFID production network,” Jenny added. “This ensures our customers benefit from a supply chain that is scalable, reliable and agile.”

Most recently, Checkpoint achieved SOC 2 Type II and SOC 1 Type II certification for its ItemOptix Software platform, further demonstrating its commitment to data security, reliability and customer trust.

Looking ahead, Jenny outlined the company’s short and long-term priorities as it continues to expand its presence across packaging, warehousing and logistics.

Looking ahead, Jenny outlined the company’s short and long-term priorities as it continues to expand its presence across packaging, warehousing and logistics.

“Our plans for 2026 are centred on continuing to support our customers – whether that’s maintaining their existing EAS systems or helping them transition into RFID to gain better insight into purchasing behaviour and sales performance,” she said. “We will also continue expanding within the logistics sector, supporting distribution centres with RFID solutions that simplify processes, improve asset visibility and strengthen warehouse-to-store tracking.”

She added that Checkpoint remains committed to guiding businesses through every stage of their RFID journey.

“No matter the industry, we have the capabilities to support customers from manufacturing through to the end user, delivering bespoke solutions tailored to their specific needs.”

Closing the conversation, Jenny shared her appreciation for being recognised as Security & Loss Prevention Company of the Year.

“We’re absolutely honoured to receive this award from Packaging, Warehouse & Logistics. 2025 was a hugely important year for us within the logistics industry, and it’s been fantastic working with PWL across articles, sponsorships and our Company of the Month feature. To now be recognised as Company of the Year is a real privilege, and we look forward to continuing our collaboration in the future.”

T 01635 567070

ukinfo@checkpt.com

https://checkpointsystems.com