Throughout distribution and manufacturing sectors, competitive pressures are driving the demand for faster, more accurate order fulfilment. For many manufacturers and operators of industrial processes, demand is growing for real-time access for replacement inventory and spare parts to ensure uninterrupted operation.

The use of automated, software-driven solutions such as vertical carousels, vertical lift systems, vertical Buffer modules and horizontal carousels for inventory picking can slash fulfilment times, labour needs, and warehouse footprint requirements, while vastly improving throughput and worker productivity. To meet this demand the goal is to use a combination of automation technologies and improved workflow processes to reduce the time required to pick, pack and ship items. Such an approach can help warehouses and distribution facilities to become more productive and competitive.

The use of automated, software-driven solutions such as vertical carousels, vertical lift systems, vertical Buffer modules and horizontal carousels for inventory picking can slash fulfilment times, labour needs, and warehouse footprint requirements, while vastly improving throughput and worker productivity. To meet this demand the goal is to use a combination of automation technologies and improved workflow processes to reduce the time required to pick, pack and ship items. Such an approach can help warehouses and distribution facilities to become more productive and competitive.

A variety of automation technologies are available to improve both the speed and accuracy of the picking process and workflow. When dynamic storage systems are coupled with improved workflow procedures related to order-fulfilment, picking and shipping, facilities can drastically improve overall inventory management within the facility and boost customer satisfaction.

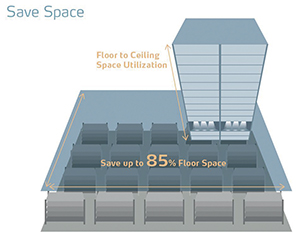

Automated storage solutions are used by many for improved space utilisation. By maximising the use of under-utilised overhead space from the floor to the ceiling, traditional floor space requirement can be reduced by as much as 65-85%. For many it can mean the difference between staying put or moving to larger premises. Another major factor is improved working conditions. Automated solutions are designed with the worker in mind. Not only do they help to reduce foot travel but are ergonomically designed. By bringing the goods to the person, bending, reaching and carrying is greatly reduced, which is faster and safer for staff.

Automated storage solutions are used by many for improved space utilisation. By maximising the use of under-utilised overhead space from the floor to the ceiling, traditional floor space requirement can be reduced by as much as 65-85%. For many it can mean the difference between staying put or moving to larger premises. Another major factor is improved working conditions. Automated solutions are designed with the worker in mind. Not only do they help to reduce foot travel but are ergonomically designed. By bringing the goods to the person, bending, reaching and carrying is greatly reduced, which is faster and safer for staff.

Today, a variety of automation technologies and optimisation strategies are available to help warehouse operators overcome the limitations and inefficiencies of the manual approach. And because these technology options are essentially modular in nature, today’s automated systems can be phased in over time. This gives warehouse managers great flexibility in terms of managing expenses and training issues and analysing ongoing results to both fine‐tune ongoing optimisation efforts and analyse return on investment (ROI).

Today, four main technology options are available for automating the storage and retrieval of individual SKUs, and for improving operational efficiency: Vertical lift modules (VLMs), Vertical carousels, Virtual Buffer Modules (VBMs) and Horizontal carousels. These solutions enable warehouse operators to spread investment costs over time, move certain parts of the overall inventory into the automated solutions, support staff and analyse the experience over time to determine time and labour savings.

To learn more about dynamic storage solutions, contact Kardex Remstar at: info.remstar.uk@kardex.com or visit our website at: www.kardex.com