In this issue of Industrial Process News, we are proud to announce NIRONIT Edelstahl GmbH & co. KG as our Stainless Steel Specialist Company of the Month.

The global stainless steel market size is thought to be now worth in excess of $183.86 million, with ferritic stainless-steel in particular accounting for a large market share. The demand for stainless-steel continues to rise across the public and private sectors, across infrastructures such as residential housing, automotive, railways and process industries. Stainless-steel has always been regarded as more robust than carbon steel or weathering steel, with its superior qualities: corrosion-resistant, low maintenance costs, high pliability and longer average product life-cycle. With its famed tensile strength properties, stainless steel is widely used in piping systems, pumps and storage systems.

The global stainless steel market size is thought to be now worth in excess of $183.86 million, with ferritic stainless-steel in particular accounting for a large market share. The demand for stainless-steel continues to rise across the public and private sectors, across infrastructures such as residential housing, automotive, railways and process industries. Stainless-steel has always been regarded as more robust than carbon steel or weathering steel, with its superior qualities: corrosion-resistant, low maintenance costs, high pliability and longer average product life-cycle. With its famed tensile strength properties, stainless steel is widely used in piping systems, pumps and storage systems.

The COVID-19 pandemic had a huge impact on global stainless-steel production, with many Asian companies ceasing manufacturing completely. Italian steel mills lost significant sales volumes and there have been substantial delays in stainless slab imports. NIRONIT was mildly affected but due to the foresight of excellent crisis management planning, managed to weather the storm.

NIRONIT has been a leading stainless-steel manufacturer for over 40 years, supplying to diverse sectors from chemical, shipbuilding, pump construction to agriculture. A recent merger with FERRIT-Blechservice GmbH & Co. KG has significantly increased the stainless-steel production capacity. Offering a truly first-class service, this reputable company is able to offer premium standard-sized or bespoke-ordered products.

Established in 1982 by Thomas Meyer (CEO), the company has expanded to become leading German experts in the stainless-steel field. With the headquarters in Lower Saxony, Rosengarten, production facilities in Bremen and warehouses in Lower Saxony, Prinzhöfte; the company boasts of an unrivalled stock of stainless-steel plates and coiled sheets up to 14,000mm. NIRONIT has an extensive stock collection for any steel project: from retail steel fabrication to railway networks.

Established in 1982 by Thomas Meyer (CEO), the company has expanded to become leading German experts in the stainless-steel field. With the headquarters in Lower Saxony, Rosengarten, production facilities in Bremen and warehouses in Lower Saxony, Prinzhöfte; the company boasts of an unrivalled stock of stainless-steel plates and coiled sheets up to 14,000mm. NIRONIT has an extensive stock collection for any steel project: from retail steel fabrication to railway networks.

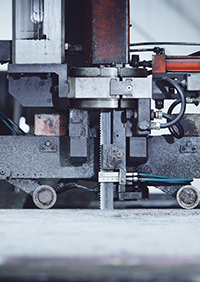

The expert engineering production team in the service centre, uses state-of-the-art cutting machinery to a wide range of specifications. The new HiFocus Plasma Cutting machinery has an impressive dimension range: cutting up to 40mm thickness, outside tolerance +3mm and inside tolerance –3mm. The FineFocus is similarly impressive: cutting up to 150mm, up to +10mm outside tolerance and –10mm inside tolerance.

The precision-driven CNC-controlled waterjet offers pinpoint high-surface cut edges, with very tight tolerances. The dimensions range and table sizes are impressive: 2,010 x 4,010mm, 3,000 x 6,150mm and 3,000 x 9,880mm.

Specific sawing can cut round stock up to 660mm diameter and flat stock up to 660 x 1,060mm length (minimum length: 20mm). The band saw cuts all flat and rectangular dimensions from steel plates, with a dimension range of 2,500 x 6,250 x 300mm. The advantages of using a band saw are right-angled clean-cut edges and a flexibility in width strips. We chatted to Christoph Werth: Head of Global Sales to find out more about NIRONIT, “We are stainless steel experts, with over 40 years international trade experience. We specialise in special grades, coils, plates and cuttings. With our own warehouse and service center with waterjet, plasma, saw, bevelling machine and deburring machine, we can deliver stock quickly and have expertise with customs processing. Our customers span across four continents: Europe, Asia, Africa and South America.”

Specific sawing can cut round stock up to 660mm diameter and flat stock up to 660 x 1,060mm length (minimum length: 20mm). The band saw cuts all flat and rectangular dimensions from steel plates, with a dimension range of 2,500 x 6,250 x 300mm. The advantages of using a band saw are right-angled clean-cut edges and a flexibility in width strips. We chatted to Christoph Werth: Head of Global Sales to find out more about NIRONIT, “We are stainless steel experts, with over 40 years international trade experience. We specialise in special grades, coils, plates and cuttings. With our own warehouse and service center with waterjet, plasma, saw, bevelling machine and deburring machine, we can deliver stock quickly and have expertise with customs processing. Our customers span across four continents: Europe, Asia, Africa and South America.”

NIRONIT stocks all classic stainless-steel such as: 304/304L, 316L, 316Ti and 321, as well as numerous special grades that are used in various apparatus and projects. There has been a recent addition of new cutting-edge machinery to enhance manufacturing and production as Gioia explains further.

“We have a new deburring & levelling machine by ARKU. The edgebreaker is universally applicable, with unique edge rounding up to 2.0mm. The flatmaster has a powerful, unrivalled performance: with servo-hydraulic straightening gap control, hydraulic overload protection to protect drive and straightening unit, allowing reproducible straightening results. From small to thick: material thicknesses 0.5mm to 60mm and covers most diverse parts: maximum passage widths from 800mm to over 3,000mm.”

“We have a new deburring & levelling machine by ARKU. The edgebreaker is universally applicable, with unique edge rounding up to 2.0mm. The flatmaster has a powerful, unrivalled performance: with servo-hydraulic straightening gap control, hydraulic overload protection to protect drive and straightening unit, allowing reproducible straightening results. From small to thick: material thicknesses 0.5mm to 60mm and covers most diverse parts: maximum passage widths from 800mm to over 3,000mm.”

ARKU was founded in 1928 and is world leading with its high-capacity, precision levelers, deburring and edge rounding machinery. NIRONIT has always used premium deburring machinery, allowing consistent, exceptional quality for customers all around the world.

Laser or plasma cutting can leave residue on the edges, compromising the downstream processing. Parts with burrs are tricky to assemble and ultimately may not fit securely into welding fixtures. Deburring removes these small imperfections: burrs and with laser cutting, the burr will be removed from the part. Automated deburring has multiple benefits: removing residue, rounding sharp edges after punching or cutting, surface finishing and removing oxide layers left from laser cutting with oxygen. The oxide layer can cause unclean weld seams and corrosion, if not removed.

There are additional health and safety risks with unrounded edges: causing potential injuries and logistically: more cumbersome to apply paint further down the line.

There are additional health and safety risks with unrounded edges: causing potential injuries and logistically: more cumbersome to apply paint further down the line.

Having deburred sheet metal parts are a guaranteed sign of high-quality and give companies an edge over competitors.

NIRONIT is an innovative company and has also invested in a new laser system, to continue its excellent, experienced customer service. With its longstanding commitment to customer expertise, NIRONIT can set up a repeat ordering service, based on pre-arranged fixed prices. This cost predictability, in the current cost-of-living crisis is advantageous, allowing companies to plan annual budgets, with guaranteed assurance of delivery on-time.

NIRONIT prides itself on only offering the highest-quality products: using method testing methods, all products are inspected before, during and after production, ensuring a streamlined inspection process. For added reassurance, there is an in-built quality management system, adhering to DIN EN ISO 9001: 2015 by TÜV Nord.

For more information or to see the full stainless-steel range, see below:

For more information or to see the full stainless-steel range, see below:

T +49 4108 4301-11

christoph.werth@nironit.de

www.nironit.de