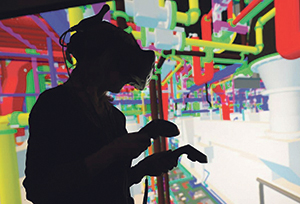

More-and-more engineering and manufacturing organisations are turning to immersive technology to improve their product design and development processes – whether those products are cars, submarines, aeroplane engines, agricultural equipment, and many others. Whatever you need to design this technology will help you to do that more accurately in half the time.

For over 30 years, Virtalis has been working with these organisations not just to add immersive technology to their processes, but to train and integrate it with their workforces and supply chains. Our team of experts will work closely with you to ensure that you get the most out of our cutting-edge VR technology, and we’ll bring our wealth of experience to help you unlock its full potential. Here are three key areas we can help you do that:

For over 30 years, Virtalis has been working with these organisations not just to add immersive technology to their processes, but to train and integrate it with their workforces and supply chains. Our team of experts will work closely with you to ensure that you get the most out of our cutting-edge VR technology, and we’ll bring our wealth of experience to help you unlock its full potential. Here are three key areas we can help you do that:

- Deliver products right first time

Any manufacturer will be familiar with the need to get products right first time – issues that slip by the initial design phase lead to frustrating delays in delivery, costly rework, and customers left disappointed by the final product.

But designers can use solutions such as Virtalis’ Visionary Render to carry out virtual design reviews and prototyping. Rather than working from flat 2D drawings, virtual reality gives everyone involved from the process a way to step into designs and understand them more fully. That gets everyone on the same page more quickly and provides opportunities for teams to give feedback and catch flaws earlier in the process.

For example, human factors and ergonomics are a key part of a design process that traditionally gets involved later down the line. By translating the early designs into virtual prototypes, human factors experts can use virtual manikins to confirm that a final product can accommodate a real human being rather than working with a stiff physical manikin – whether that’s checking the reach from a worker’s desk to a needed tool, or if a lever will impede someone’s line of sight.

For example, human factors and ergonomics are a key part of a design process that traditionally gets involved later down the line. By translating the early designs into virtual prototypes, human factors experts can use virtual manikins to confirm that a final product can accommodate a real human being rather than working with a stiff physical manikin – whether that’s checking the reach from a worker’s desk to a needed tool, or if a lever will impede someone’s line of sight.

Many Virtalis customers use virtual prototypes rather than building physical ones. Iterative design can happen quickly and at far less cost than constantly building and rebuilding physical prototypes. The virtual prototype can often bring in much more detail than a physical one too, leading to more accurate decisions being made.

For one Virtalis customer, these virtual design reviews helped it to avoid late rework changes that can cost more than six-figures each time. Another customer of ours has seen 67% of its designs signed off on the virtual model alone. This means that it can invoice for work much earlier than before. And another customer has noted seven-figure savings in just one optimisation case when it implemented Virtalis solutions.

- Collaborate with teams wherever they are

Even before remote work became more the norm, plenty of teams had to work together either within their own organisations across different locations, or with suppliers based around the world. That allows access to expertise no matter where someone might be based as well as leading to huge savings in time and money when travel can be avoided – not to mention the sustainability benefits too. Immersive solutions can bring these teams together in a far more productive way than a simple video call. Team members can come together with virtual reality headsets in a virtual environment to review designs, allowing them to get a better feel for designs compared to screen sharing PowerPoint slides.

Even before remote work became more the norm, plenty of teams had to work together either within their own organisations across different locations, or with suppliers based around the world. That allows access to expertise no matter where someone might be based as well as leading to huge savings in time and money when travel can be avoided – not to mention the sustainability benefits too. Immersive solutions can bring these teams together in a far more productive way than a simple video call. Team members can come together with virtual reality headsets in a virtual environment to review designs, allowing them to get a better feel for designs compared to screen sharing PowerPoint slides.

A manufacturer customer uses a Virtalis solution of software and an immersive wall to work with its suppliers. In one case, it undertook a collaborative redesign effort with a critical supplier to modernise a component. With a drawing package over 400 pages, the supplier was not confident all upgrades could be made. The customer used Virtalis software to connect its own design centre to the supplier’s site, facilitating real-time remote collaboration on the redesign effort.

Other Virtalis customers and their teams have commented that by working with designs and models in virtual reality, they get a much truer sense of what the final product will be. Indeed, one user said that when they visited a finished factory, it felt as if they had been there several times before thanks to being immersed in the virtual model. And thanks to the accuracy of the virtual model, the customer estimated that on-site engineer visits had been reduced by 30%.

- The technology gets your product to market faster

Improving time to market is a key objective for many organisations. Getting your product out faster means bringing in revenues faster, lower overall costs, and a greater chance at taking the first-mover advantage.

Improving time to market is a key objective for many organisations. Getting your product out faster means bringing in revenues faster, lower overall costs, and a greater chance at taking the first-mover advantage.

As well as the cost savings that can be achieved with immersive technology and virtual design reviews, these techniques can hugely speed up the product design and development cycle.

From the outset, designs can be communicated far more easily and far more quickly with a virtual model, since an immersive 3D model is easier to understand than flat 2D drawings or complicated CAD data. So, better decisions can be made much faster. This benefit is multiplied when working with tools provided by Virtalis since huge models can be viewed incredibly quickly, making it even easier for everyone to get a better sense of the overall design at once.

Virtual prototypes save time as well as money. Changes made in the design are reflected instantly in a virtual model, meaning designers can avoid the lengthy building and rebuilding of a physical prototype.

Several Virtalis customers have seen the benefit. For example, one customer’s redesign project with its supplier finished an entire eight months of its 18-month schedule. Another customer reduced its average work cell adaptation lead time by 25%. And a third has reduced project delivery times by 25%, with safety reviews taking hours rather than weeks, and concept development time reduced by two years.

Immersive technology has a huge role to play for engineers and manufacturers, whatever their products are. However, taking advantage of this kind of innovation is about more than purchasing a software application or piece of hardware. This is why Virtalis partners with organisations to deliver not just the initial solution, but to support them in realising and measuring the benefits to be had on an ongoing basis.

Are you ready to unlock the full potential of virtual reality for your business? Schedule a consultation with our team of VR experts. We’ll work with you to understand your business needs, identify areas where VR can have the biggest impact, and develop a customised solution that fits your specific requirements.

Contact n.cregan-evans@virtalis.com

T +44 (0)161 969 1155

marketing@virtalis.com

www.virtalis.com