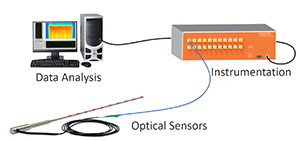

Proximion is a world leader in the design and manufacturing of systems based on advanced Fibre Bragg Gratings (FBGs) which are primarily used for fibre optic communication. Proximion’s FBG solutions are extremely efficient in optimising data transfer over long distances via fibre optic networks.

Proximion is a world leader in the design and manufacturing of systems based on advanced Fibre Bragg Gratings (FBGs) which are primarily used for fibre optic communication. Proximion’s FBG solutions are extremely efficient in optimising data transfer over long distances via fibre optic networks.

You’ll find Proximion’s technology used across the ten leading system vendors that represent approximately 90% of the telecommunications market, however, this versatile technology is also extremely useful for temperature and strain sensing within numerous industrial sectors.

“Proximion provides fibreoptic technology to two markets: the telecoms market, where its solutions increase the performance, security and cost-effectiveness of communications networks, and the laboratory and industrial sensing markets where its solutions offer actionable measurements for process optimisation and control,” stated Chris Staveley, Business Development Consultant.

Compared to conventional electronic sensing, Proximion’s fibreoptic sensing offers a vast number of benefits including: high speed, high accuracy measurements; insensitivity to electro-magnetic fields; intrinsic safety; one or few connections vs. hundreds for traditional electronic sensor installations; highly distributed linear (1D), area (2D) or volumetric (3D) measurements; miniature sensing fibres that are easily embedded into a structure; and significant cost advantages compared to high-count traditional monitoring.

Established in Sweden by a group of technical experts who held vast amounts of knowledge and expertise in the field of optical fibre technology for the telecoms market, Proximion has gone from strength to strength over the years and is now part of the Hexatronic Group, which is well respected for its fibreoptic technology across the globe.

There are two applications worth noting here.

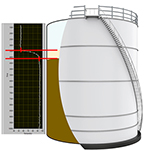

Firstly, fluid level monitoring with fibreoptic temperature sensing arrays. Many chemical processes include storage tanks where process fluids enter and leave, and knowledge of the process fluid levels and stratification is of great value. Deploying a Proximion sensing fibre vertically within the tank provides a high-resolution temperature profile of the fluid column from which the fluid interfaces can be determined in real time. A good example of this was in a recent case study from a Kraft pulping process where wood is converted into wood pulp containing cellulose fibres for the production of paperboard and paper, and where the production of high-value secondary product streams such as lignosulfonates and crude tall oils can be extremely challenging. Proximion’s optical fibre array temperature sensing is ideally suited to meet this measurement challenge by using miniature fibre Bragg grating sensors that support a large number of measurement points using only one single sensing cable. The high-resolution temperature profile generated by such an optical fibre array is processed in real-time to show process engineers the fluid interfaces within the tank, from which they can optimise the production of the valuable secondary products. Together with a leading Swedish pulp and paper producer, Proximion engineers have completed pilot trials that demonstrate the value of fibre optic multi-point temperature sensing in this and several other potential applications.

Firstly, fluid level monitoring with fibreoptic temperature sensing arrays. Many chemical processes include storage tanks where process fluids enter and leave, and knowledge of the process fluid levels and stratification is of great value. Deploying a Proximion sensing fibre vertically within the tank provides a high-resolution temperature profile of the fluid column from which the fluid interfaces can be determined in real time. A good example of this was in a recent case study from a Kraft pulping process where wood is converted into wood pulp containing cellulose fibres for the production of paperboard and paper, and where the production of high-value secondary product streams such as lignosulfonates and crude tall oils can be extremely challenging. Proximion’s optical fibre array temperature sensing is ideally suited to meet this measurement challenge by using miniature fibre Bragg grating sensors that support a large number of measurement points using only one single sensing cable. The high-resolution temperature profile generated by such an optical fibre array is processed in real-time to show process engineers the fluid interfaces within the tank, from which they can optimise the production of the valuable secondary products. Together with a leading Swedish pulp and paper producer, Proximion engineers have completed pilot trials that demonstrate the value of fibre optic multi-point temperature sensing in this and several other potential applications.

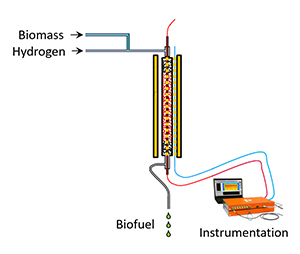

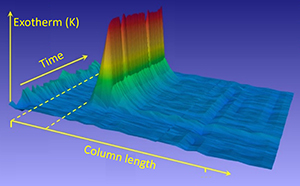

The second application worth nothing is the monitoring of exothermic reactions in column reactors, which is a new use of optical fibre sensing technology for the chemical process industry. Proximion’s fibreoptic sensing provides a solution to this monitoring challenge and has been proven through a collaboration with the Research Institute of Sweden (RISE), where a biofuel reactor was successfully instrumented, and valuable measurements were obtained and analysed.

The packed bed reactor is the most common chemical reactor design, and Proximion was challenged to find a solution to the cumbersome process of monitoring these reactors accurately. FBG sensors are made inside miniature (<=250µm) optical fibres and have a very small form-factor, and therefore were ideally suited to this challenge. An experimental packed bed reactor with Proximion fibre optic temperature array sensors was built at RISE to evaluate this new technology application. The sensing system demonstrated the capability to measure the relatively minor exothermic reactions that occur along the complete length of the column, allowing the RISE process engineers to optimise the reactor conditions for maximum conversion efficiency.

The packed bed reactor is the most common chemical reactor design, and Proximion was challenged to find a solution to the cumbersome process of monitoring these reactors accurately. FBG sensors are made inside miniature (<=250µm) optical fibres and have a very small form-factor, and therefore were ideally suited to this challenge. An experimental packed bed reactor with Proximion fibre optic temperature array sensors was built at RISE to evaluate this new technology application. The sensing system demonstrated the capability to measure the relatively minor exothermic reactions that occur along the complete length of the column, allowing the RISE process engineers to optimise the reactor conditions for maximum conversion efficiency.

Proximion’s applications and systems are ideal for laboratory technicians, researchers, and industrial process control engineers. As your trusted advisor in fibre optic sensing, Proximion can create solutions that deliver clear value to you.

Proximion will be exhibiting at Lab Innovations on the 1st-2nd November 2023 at the NEC in Birmingham on Stand A46.

For more information, please see below:

https://www.proximion.com