The increasing need for higher sustainability of our time is also reflected in the acceptance in solutions of 2-component discharge systems. These developments can make a relevant contribution to higher environmental compatibility of corresponding adhesives and sealants.  Ecological and social challenges, as well as the use of environmentally friendly materials and improvements to energy efficiency, are key factors that must be considered when developing new solutions. By using recycled or bio-based materials and power saving production processes, companies can play their part in protecting the environment by reducing their carbon footprint. However, that alone is often not enough. To make products even more sustainable, the consistent use of eco-design principles is crucial. For example, reducing material or using a less carbon intensive plastic can help to further minimise the product’s overall ecological footprint.

Ecological and social challenges, as well as the use of environmentally friendly materials and improvements to energy efficiency, are key factors that must be considered when developing new solutions. By using recycled or bio-based materials and power saving production processes, companies can play their part in protecting the environment by reducing their carbon footprint. However, that alone is often not enough. To make products even more sustainable, the consistent use of eco-design principles is crucial. For example, reducing material or using a less carbon intensive plastic can help to further minimise the product’s overall ecological footprint.

Multiple challenges

There are many different challenges in the development of packaging solutions for 2-component dispensing systems: The safe use of the cartridges and the storage stability of the components are important functionalities that must be secured during development. The parts of the solution must be designed in a way that the materials in the cartridges do not react prematurely and thus lose their functionality. Regulatory requirements also play a vital role in the development of these packaging solutions. In addition, the ecological footprint is becoming increasingly significant. The products must be both functional and safe, while being produced in an environmentally friendly manner.

In order to develop a sustainable solution for 2-component dispensing systems, economic, ecological and technical requirements must be harmonised. To achieve this, various analysis and simulation methods are combined to form a digital development chain. Using this approach, it is possible – even in an early development stage – to optimally consider the required product performance, the manufacturing costs and overall sustainability.

Digital simulations

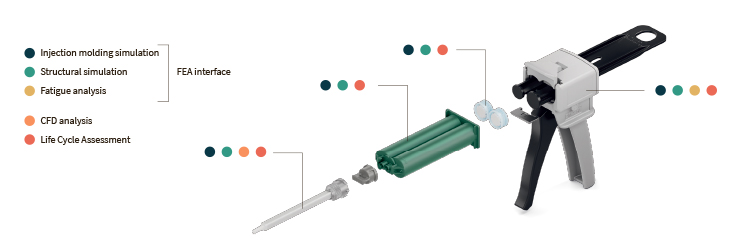

With the aid of a filling simulation, the injection moulding process is analysed before an initial tool has even been produced. This allows an early identification of possible issues that would occur during the final process. Suitable measures can then be taken, for example, to avoid air inclusions, move weld lines to non-critical areas and optimise fibre orientations. Furthermore, this simulation provides essential information on shrinkage and distortion of the components during the cooling process. Since the filling process strongly influences production costs, early simulation offers huge potential to improve product profitability.

Analysis of the mechanical integrity of the components starts in parallel with the filling simulation. In addition to analytical approaches, the finite element method is used. This computational simulation process analyses both the rigidity and the strength of the products to be manufactured. If cyclic loads also occur in the subsequent application, fatigue calculations are performed downstream to estimate the expected service life. Due to the close coupling of filling and structural simulations, manufacturing influences are directly considered in the structure calculation and significantly increase its informative value.

CFD (computational fluid mechanics) simulations are used to develop geometries for the mixing of 2-component adhesives. Considering the often-complex rheological properties of the adhesives and the conditions of use, the most efficient mixing technology can be selected or developed. In this context, efficient means achieving a specified mixing quality of the adhesive components with the lowest possible pressure loss and the smallest possible mixer geometry.

Calculating the ecological footprint

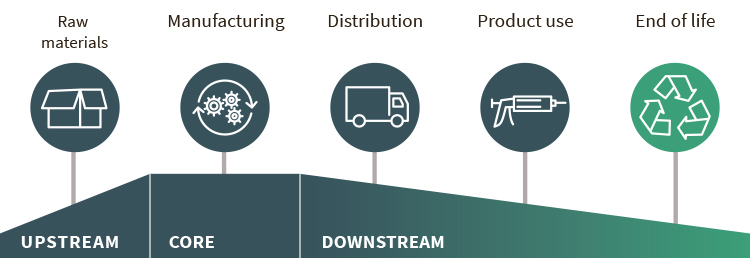

Environmental performance evaluation software is used to calculate and simulate the ecological footprint of a product. The environmental performance evaluation assesses the environmental impact of a product over its entire life cycle, from raw material extraction to disposal. This life cycle can be divided into three phases. The first phase, Upstream, comprises the raw material extraction and production of the preliminary products needed to manufacture the product. The second phase, Core, refers to the transport of the preliminary products and the actual manufacture of the product, including packaging. The third phase, Downstream, includes the distribution, use, disposal, and recycling of the product. By identifying weak points in the system, optimisation potential can be uncovered and exploited.

By integrating these different simulation tools, developers can simulate the entire development process (known as a digital twin) and thus save time and costs. In addition, they can optimally adapt the system to the specific requirements and improve the sustainability of the process.

Cartridges made from recycled plastic

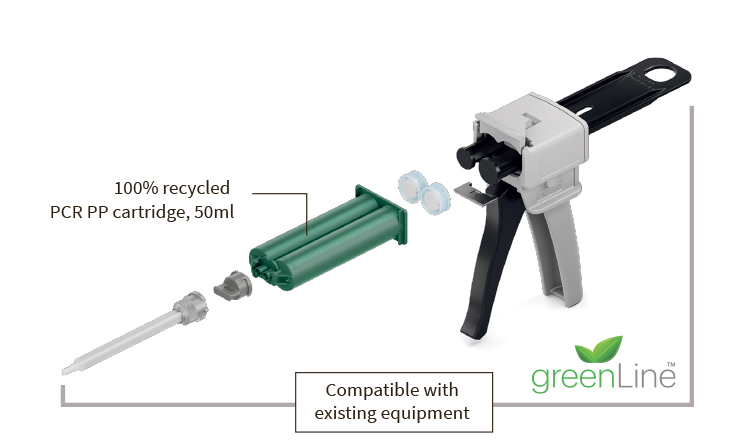

A way to develop a sustainable solution with the lowest barriers to entry for all stakeholders in the 2-component dispensing system value chain is the use of recycled plastic from packaging waste for the complete cartridge system. Optimisations in the upstream and core product lifecycle phases can reduce the ecological footprint. This incremental approach may be implemented by customers (developers of 2-component materials and cartridge fillers) as a drop-in solution since existing processes can be used for manufacturing. On the user side, there is no need for adjustments to the filling process or application routines since nothing changes in the design of the products. Using recycled plastic enables both ecological and regulatory requirements to be met. At the same time, this solution offers the advantage of rapid implementation as no new production equipment or changes in the proven processes are needed.

More ecological packaging concept

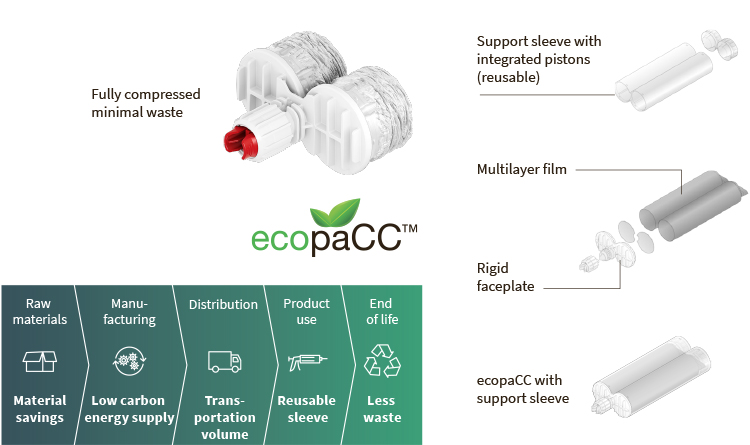

A new packaging concept using eco-design principles enables additional sustainability potential to be tapped. With this radical and innovative solution, improvements can be achieved in all phases of the product life cycle. Compared to the drop-in solution, optimisation is also possible in the downstream phase.

The use of flexible packaging for most of the cartridge enables material to be saved, reducing transportation volume. A reusable support cartridge has been developed for the application, which helps to lower the ecological footprint. Only the disposable part of the packaging is discarded at the end of the life cycle, thereby significantly reducing the amount of waste.

The advantage of this solution is that it achieves a large saving via the packaging design, while at the same time improving the sustainability of the product through reusable elements and less waste. Overall, this packaging concept is an example of how ecological and economic requirements can be harmonised in product development to create a more sustainable solution.

Taking the entire value chain into account

In summary, sustainability is playing an increasingly important role in the product development of 2-component dispensing systems for adhesives and sealants. To meet environmental and social challenges, economic, ecological, and technical requirements must be harmonised. In this case, a digital development process with simulation tools can help to form a closed simulation chain and provide accurate data on sustainability. Sustainable packaging concepts can achieve savings throughout the entire life cycle. It is important to consider the whole value chain to develop a sustainable solution and contribute to a better future.

Author

Author

Tobias Bodenmüller

Technology Expert

medmix Switzerland AG

Ruetistrasse 7, 9469 Haag, Switzerland

www.medmix.swiss