Industrial Process News would like to award Grenville Engineering Company of the Month for innovative services.

Grenville Engineering has been a leading Precision Sheet Metal Fabricator for the last thirty eight years. Established by Managing Director, Mark Barratt, in 1984, the company now operate from a 55,000ft2 premises in Stoke-on-Trent. The central Midlands location is ideally placed to meet customer needs across many sectors including life manufacturers, renewable energy, site services, petrochemical, medical, HVAC, rail, garden products, materials handling, yellow goods, building and automotive.

Grenville Engineering has been a leading Precision Sheet Metal Fabricator for the last thirty eight years. Established by Managing Director, Mark Barratt, in 1984, the company now operate from a 55,000ft2 premises in Stoke-on-Trent. The central Midlands location is ideally placed to meet customer needs across many sectors including life manufacturers, renewable energy, site services, petrochemical, medical, HVAC, rail, garden products, materials handling, yellow goods, building and automotive.

Helen Rawlinson, Marketing Assistant, explains how expertise is at the heart of the company, “Customer-centric solutions are at the heart of what Grenville Engineering is all about. With 25% of employees having over 20+ years of service, 7 of whom have 30+ years of service. We collaborate intensely with our customers to ensure that we produce the highest quality products from carbon steel, stainless steel and aluminium to all specifications, without compromising on quality.”

The company has one eye to the future with an extensive manufacturing apprenticeship programme with excellent retention results. Many of the senior positions started as apprentices including the Sales Director (27 years), Responsible Welding Co-Ordinator (24 years), Fabricator (20 years) and Team Leader (18 years).

The company has an in-house design team that can bring concepts to manufacturing using the latest 3D CAD software such as a recent heavy-duty weighing trolley for the retail warehousing sector. The team made a protype which included digital weighing scales and internal power supply. After regular inspections during the manufacturing process the trolley was successfully rolled out into the warehouse. The customer was delighted with the design: “Grenville Engineering are a key supplier for our fabrication needs, continuously setting a high standard of customer service, quality and delivery performance. Our strong partnership continues to grow, a testament to the performance of the company.”

The company has an in-house design team that can bring concepts to manufacturing using the latest 3D CAD software such as a recent heavy-duty weighing trolley for the retail warehousing sector. The team made a protype which included digital weighing scales and internal power supply. After regular inspections during the manufacturing process the trolley was successfully rolled out into the warehouse. The customer was delighted with the design: “Grenville Engineering are a key supplier for our fabrication needs, continuously setting a high standard of customer service, quality and delivery performance. Our strong partnership continues to grow, a testament to the performance of the company.”

This leading conglomerate offers a complete service from customer design, to laser-cutting, metal punching, plastic injection moulding, glass making, sheet metal forming, metal welding, assembly, machining through to transportation of products.

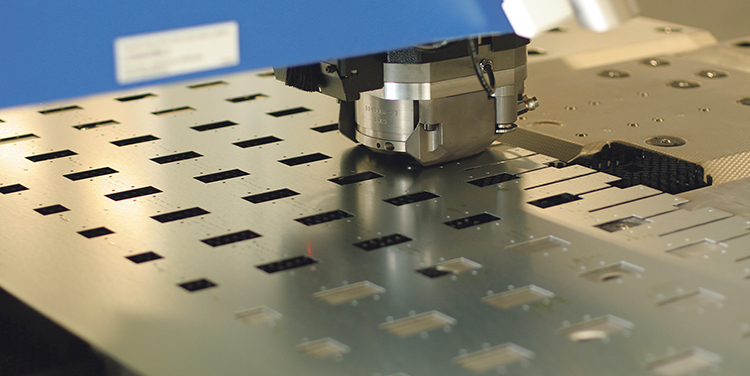

The company are committed to fabricating first-class products using the latest cutting-edge machinery. “Last year we invested over £900,000 in the latest laser cutting, bending and punching technology to increase our capabilities and capacity. One of the two key investments was a 10kW Bystronic Bysprint 3015 3000 x 1500 bed fibre laser installed in September 2021. This complemented existing 6kw and 3kW Trumpf fibre laser machines. The Bysprint cuts mild steel, stainless steel, aluminium, brass and copper, which cuts up to 25mm. The faster speed of this machine has helped us to increase our capacity and by using nitrogen can cut thicker materials which have helped us break into new markets. The other key investment was the Loewer 4TD-1000 disc master machine. Its primary function is for the edge deburring of laser cut parts to ensure the customer receives parts with the best possible finish.”

The company are committed to fabricating first-class products using the latest cutting-edge machinery. “Last year we invested over £900,000 in the latest laser cutting, bending and punching technology to increase our capabilities and capacity. One of the two key investments was a 10kW Bystronic Bysprint 3015 3000 x 1500 bed fibre laser installed in September 2021. This complemented existing 6kw and 3kW Trumpf fibre laser machines. The Bysprint cuts mild steel, stainless steel, aluminium, brass and copper, which cuts up to 25mm. The faster speed of this machine has helped us to increase our capacity and by using nitrogen can cut thicker materials which have helped us break into new markets. The other key investment was the Loewer 4TD-1000 disc master machine. Its primary function is for the edge deburring of laser cut parts to ensure the customer receives parts with the best possible finish.”

With a new 3,500ft2 manufacturing space and office facilities planned over the coming year the company are committed to expanding its existing capabilities.

The company were previously featured by IPN as one of the top exhibitors at this summer’s Subcon trade exhibition at the NEC in Birmingham. The trade promotion created interest from new industry sectors. Humanoid Productions has also recently made a bespoke corporate video creating a virtual ‘shop window’ of the fabrication process for all interested parties.

Helen illustrates the trajectory year ahead for the company, “We continue to grow year-on-year and are currently ahead of this year’s targets. We are looking to achieve a £15 million turnover within the next 5-7 years. The business is strong and agile with planned investment in automation-press and weld robotics, expansion with our skilled night shift workforce and taking on additional units has increased our capacity and opportunities whilst fitting into our long-term business plan. Along with the planned expansion, we plan on remaining an attractive place to work with good opportunities for progression to attract the right calibre employee to help facilitate the planned growth. We will be back again at Subcon 2023 for our 7th year running!”

T 01782 577929

sales@grenville-engineering.co.uk

www.grenville-engineering.co.uk