Here, iCenta explains how it field tested the Metri Pro-Lite on a large diameter water transmission pipe, evaluating its performance and suitability for such applications

Portable ultrasonic flow metering offers a practical approach to non-invasive flow measurement, eliminating the need to cut into pipes. This makes them ideal for a variety of applications, particularly where disrupting existing infrastructure is undesirable, and they are very cost-effective compared to other technologies when used on large pipelines.

Portable ultrasonic flow metering offers a practical approach to non-invasive flow measurement, eliminating the need to cut into pipes. This makes them ideal for a variety of applications, particularly where disrupting existing infrastructure is undesirable, and they are very cost-effective compared to other technologies when used on large pipelines.

Testing the Metri Pro-Lite on a 1,260mm Mains Water Pipe: The Metri Pro was used to measure the flow within a large diameter raw water transmission pipe. The reservoir was constructed in the 1980s and the pipe itself is made from Ductile iron and has a 10mm cement liner. It is 1,260mm and was deemed to be in good condition. This test aimed to assess the suitability of the system, and gain insight into its performance using the standard sensors.

Sensor Selection and Installation: The Standard 1MHz sensors, being a proven technology in production for several years, were the natural starting point. A small, medium and large sensor are available – the 1MHz sensor tested here would be considered to be the medium sized version.

Ultrasonic transit-time difference flow meters are pulse – echo systems where the two-way travel times of ultrasonic pulses are accurately measured. Typically, one pulse is sent at an angle to the flow (from precise wedge-shaped transducers) and a minute difference is measured between a pulse travelling upstream compared to a pulse travelling downstream – the ΔT time difference. These measurements resolve time differences to parts per billion and as electronics becomes more capable and at a more reasonable cost, these meters now offer outstanding value for money.

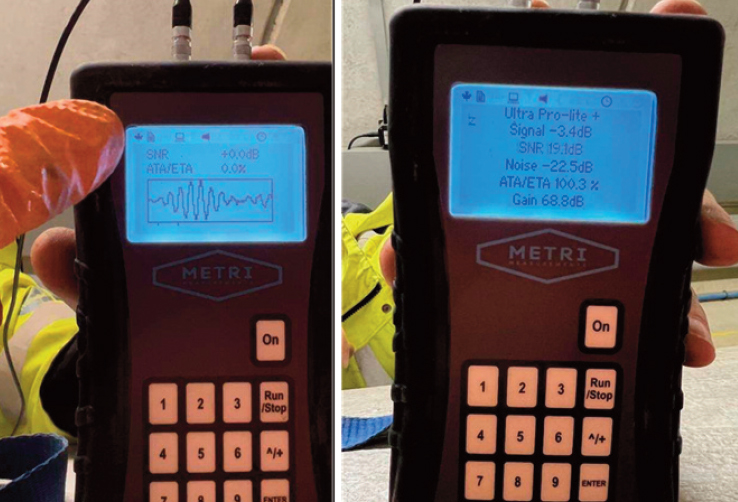

Setting the meter up is a simple procedure where you measure the pipe circumference, and enter the pipe material, fluid type, the fluid temperature, the number of acoustic traverses and any liner details. The Metri Pro-Lite has the option of using a dedicated wall thickness gauge. It has a useful A-Scan display and is a welcome addition to the system.

Setting the meter up is a simple procedure where you measure the pipe circumference, and enter the pipe material, fluid type, the fluid temperature, the number of acoustic traverses and any liner details. The Metri Pro-Lite has the option of using a dedicated wall thickness gauge. It has a useful A-Scan display and is a welcome addition to the system.

Initially, the sensors were installed in a single path or ‘Z mode’ on opposites sides of the pipe. This configuration ensures optimal signal strength. Installation involved careful alignment using a bubble level and a ratchet strap to secure the sensors in place. A good signal was immediately detected.

Evaluating ‘V Mode’ Performance: This is a large pipe, and to further explore the capabilities of the Metri Pro-Lite, the Standard 1MHz sensors were then tested, but this time in a 2 path ‘V mode’ configuration, where the sensors are on the same side of the pipe. This mode offers an alternative configuration for signal transmission and reception, and the advantage is that the ΔT time shift is doubled. While the signal strength was marginally lower in ‘V mode’ compared to ‘Z mode,’ it remained sufficiently strong for accurate flow measurement.

Key Takeaways from the Field Testing: The Field Testing successfully demonstrated the Metri Pro-Lite’s ability to measure flow accurately in large diameter (1,260mm) water pipes containing water. The tests revealed the Standard 1MHz (IC-US-M10) sensors, although physically quite small, certainly ‘pack a punch’ reliable results in both ‘Z’ as well as the more challenging ‘V’ mode. In terms of calibration, of course the water company’s data is confidential and as we logged the data, with its real time clock, we could look at the flowrates from the reference meter, and we were able to confirm a close agreement to the actual figure, within 2% of reading.

Beyond the Data: User Experience and Additional Features: In conclusion, field testing the Metri Pro-Lite on a large diameter water pipe proved its capability for non-invasive flow measurement in this challenging scenario. The Standard 1MHz sensors showed their capability on one of the larger pipes in the UK, offering reliable and a very cost-effective performance. The user-friendly design and comprehensive data logging features further enhance the value proposition of the Metri Pro-Lite, making it a compelling solution for a wide range of flow measurement needs.

iCenta have over 20 years’ experience within the ultrasonic flowmeter market. With experienced staff and a growing market, iCenta are well positioned to help with ultrasonic (and all other technology) flowmeters. Please bear in mind that ultrasonic flow meters are applicable to many process control environments and have matured into an accurate and cost-effective solution.

iCenta Controls

T 01722 439880

sales@icenta.co.uk

www.icenta.co.uk